How to Select a Door Closer

Posted by Allegion on Aug 23rd 2024

Concealed or Surface Mounted Closers

Door closers are available in two styles: concealed or surface mounted. When choosing a closer style for a particular application, consider the type of door being controlled, frame conditions, aesthetic requirements, and control features needed. The following information can serve as a guide in selecting the style and model of closer to meet specific requirements.

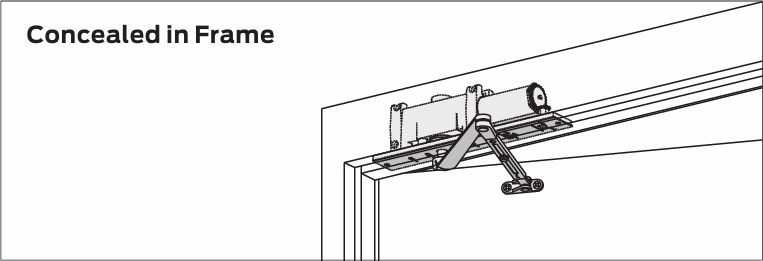

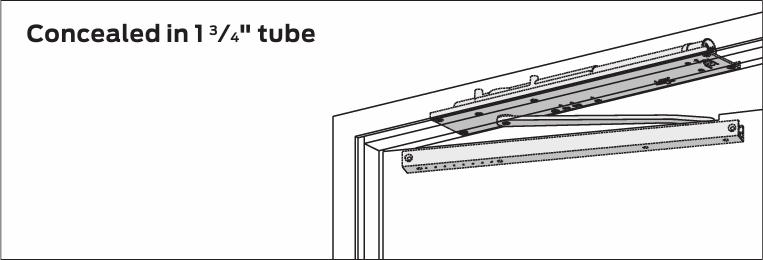

Concealed Application

Closers concealed in the head frame over the door are out of sight and out of the pedestrian's way. They are more protected from external contaminants than those mounted outside of the door and are easy to reach for regulation without removing any parts. Closers for frame sections as thin as 1 3⁄4" (44 mm) are available.

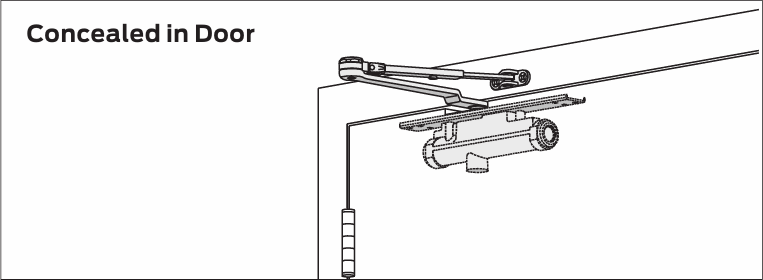

Closers located within the door itself are also hidden and protected but recommended for interior doors only.

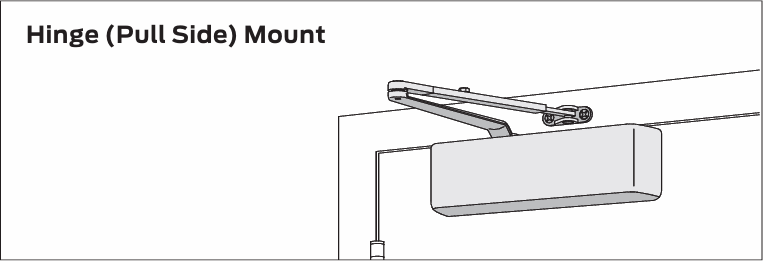

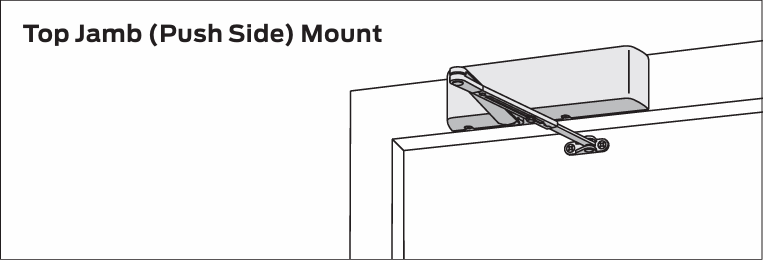

Surface Mounted Application

Closer location is subject to practicality and appearance considerations. Standard applications usually place closers on the room side of corridor doors to keep them out of the line of sight from the corridor. Closers should be placed on the inside of exterior doors for optimal aesthetics and protection from environmental elements.

Where Heavy Duty Closers are Required

Heavy duty closers are recommended in the following locations:

- Schools or public buildings where heavy or abusive usage is expected.

- Exterior doors.

- Doors subject to drafts, winds, or air pressure differentials.

- High-frequency doors such as those in department stores, malls, or mixed-use tenancies.

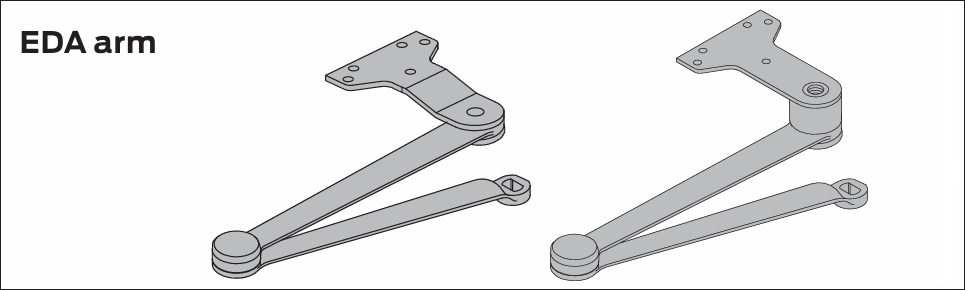

Arm System Options

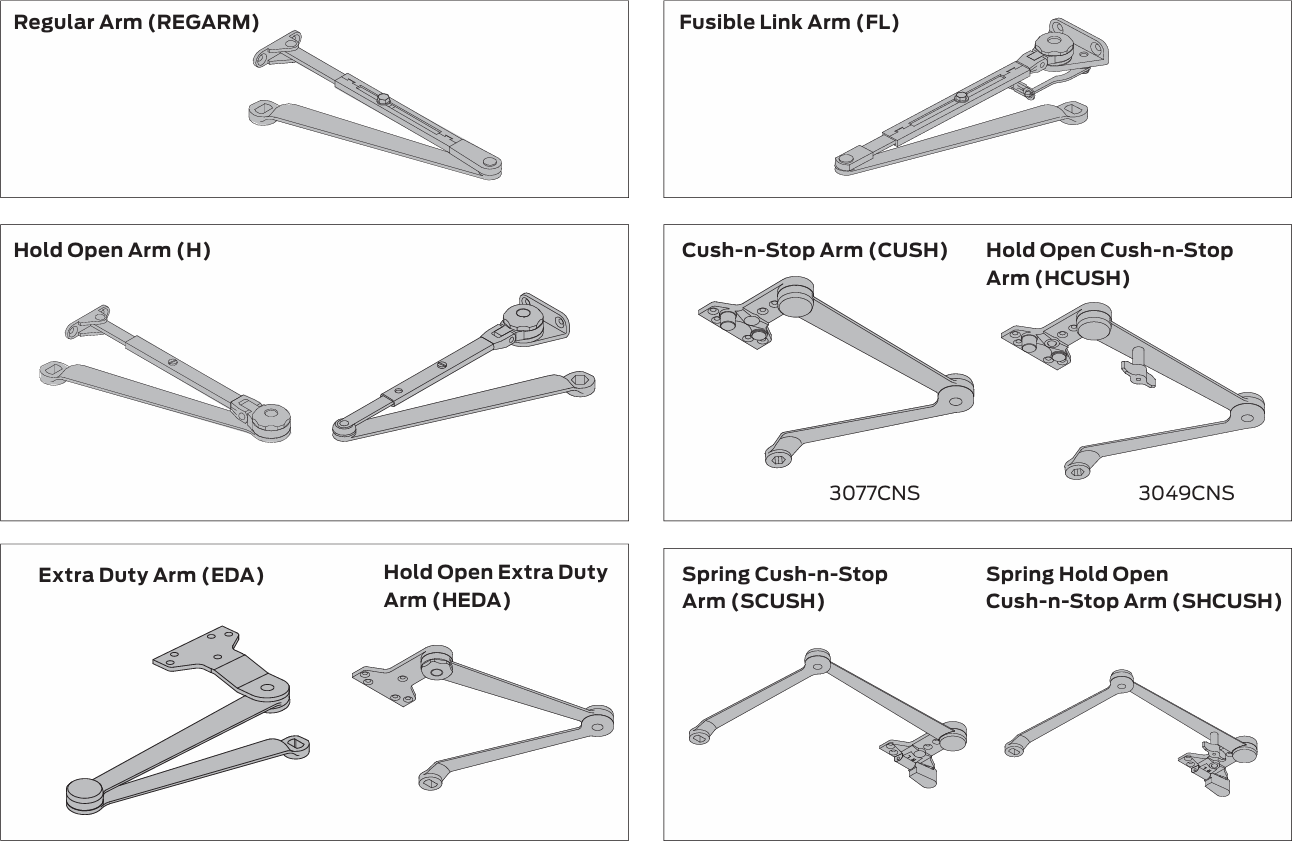

Double Lever Arm

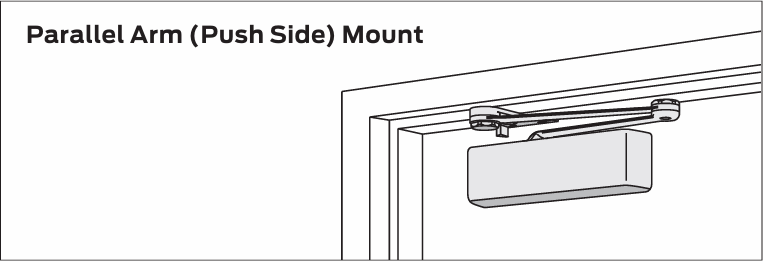

Double lever arm closers provide control under difficult conditions for either interior or exterior doors. A parallel arm system is a type of double lever arm where the main arm is parallel to the face of the closed door.

Single Lever Arm

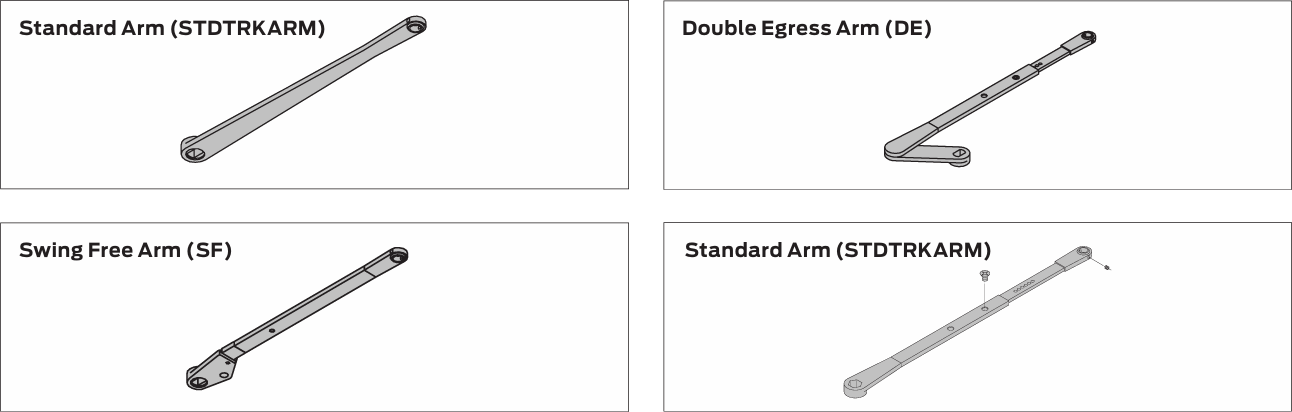

Single lever arm (track) closers may be used on interior or sheltered exterior doors. The hold open function in a single lever arm system is provided by either the track or the cylinder assembly. Available single lever arms include:

Special Cylinder Functions

Delay Action (CYLDEL)

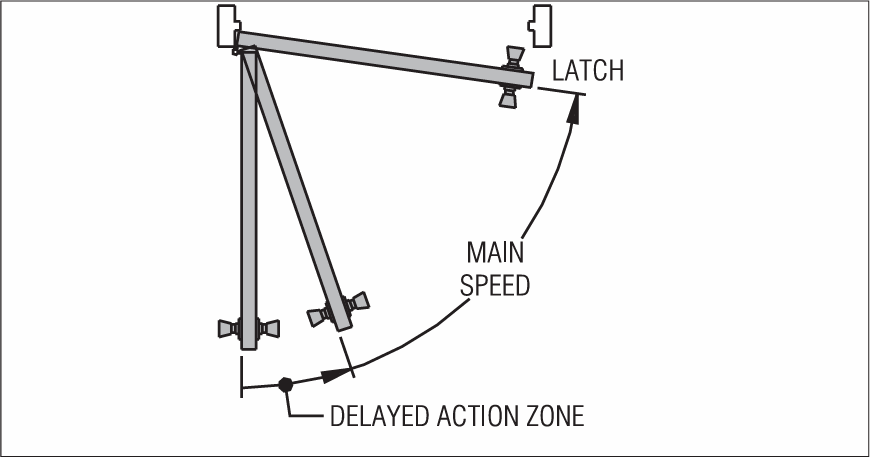

Many LCN closers can be ordered with a delayed action function built into the cylinder. This special hydraulic circuit provides additional time to pass through the door. A special regulating screw controls the closing speed from maximum opening through approximately 75°. After that point, the normal main speed resumes control to close the door. Delayed action is not available with single lever arm (track) closers.

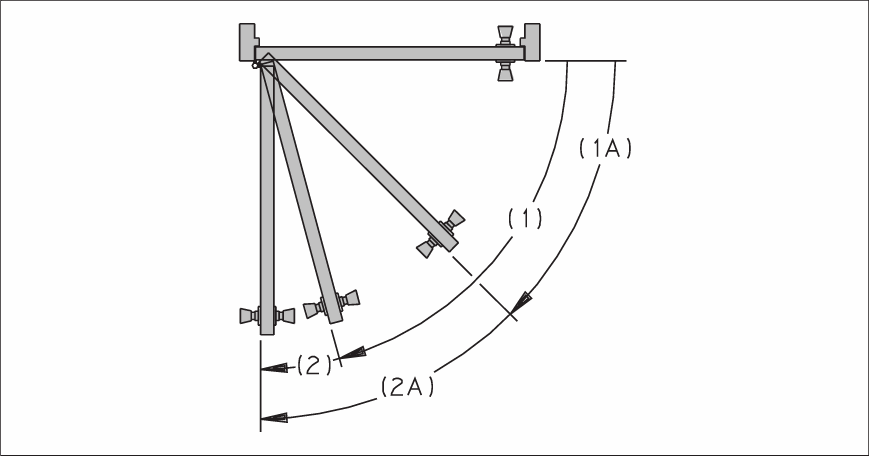

Advanced Variable Backcheck (CYLAVB)

CYLAVB is available with high security and 4110 Series closers to begin cushioning the opening swing at about 45° (2A) instead of the usual 75° (2). CYLAVB is recommended for potentially abusive applications.

Multi-point (ME Series)

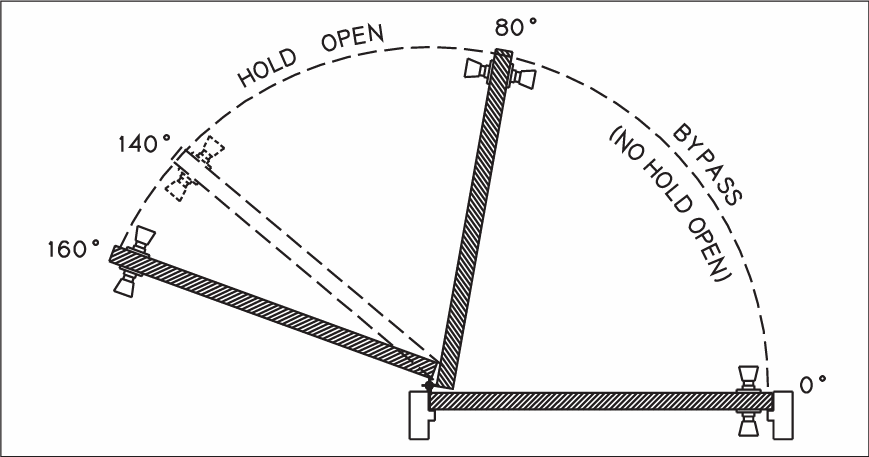

ME Series closer/holders can be ordered with a hold open bypass at either 80° or 140° function. This feature does not allow hold open to take effect until opened beyond the selected degree of bypass.

Seasonal Adjustment

Temperature changes can affect the operation of common door closers by changing the viscosity of the hydraulic fluid inside the closer. As temperature rises, the fluid thins out and closes the door more rapidly. As temperatures decrease, the fluid thickens, causing the closer to close the door very slowly. LCN’s Liquid X reduces the amount of adjustments and maintenance needed through every season.

Hanging the Doors

While butt hinges provide the most common method of hanging doors, some doors are hung on pivots centered in the door, others on offset pivots. Surface mounted closers will handle doors hung in any of these three ways. LCN 4020 Series closers can even control a “balanced” door installation. Concealed closers may conflict in location with pivot leaves and thus may require special templating.

Degree of Opening

Three basic rules apply to maximum degree of opening:

- It is best to let the door swing as far as it can swing freely. Closers are mounted in different locations for different degrees of opening.

- Use a mechanical stop when a door cannot swing 180° or at the selected hold open point of a double lever arm system. The mechanical stop can be mounted on the floor, wall, overhead, or built into the closer arm.

- The closer should be positioned so backcheck takes place well in advance of the stop position to cushion the opening swing and prevent door and frame damage from an abrupt stop.

Door Dimensions

The width of the door is the main consideration in determining the correct closer size. Size here refers to the minimum spring power and hence the closing force generated by the closer. In the catalog, the interior and exterior table of sizes for each closer is set up for ranges of door width and assumes normal operating conditions. If a door is of exceptional height, weight, special construction, or if drafts and air pressure differentials exist, increased closer power should be considered.

Door thickness may be a factor. A concealed-in-the-door closer should not be used in a hollow metal door less than 1 1⁄2" (38mm) thick or a wood door under 1 3⁄4" (44mm). Exceptionally thick doors can affect hinge and pivot centers to the extent that closer functions and geometry are also affected.

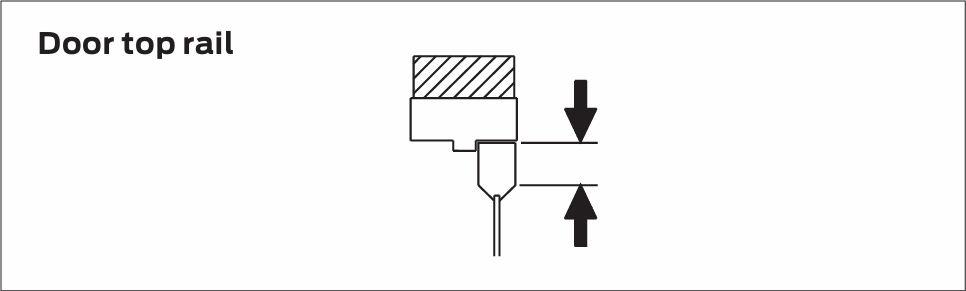

The depth of the door’s top rail is important to nearly every closer installation. Narrow top rails may require plates to successfully mount the closer. An insufficient top rail in flush, hollow, or composite-filled doors may make concealed-in-the-door installations impractical.

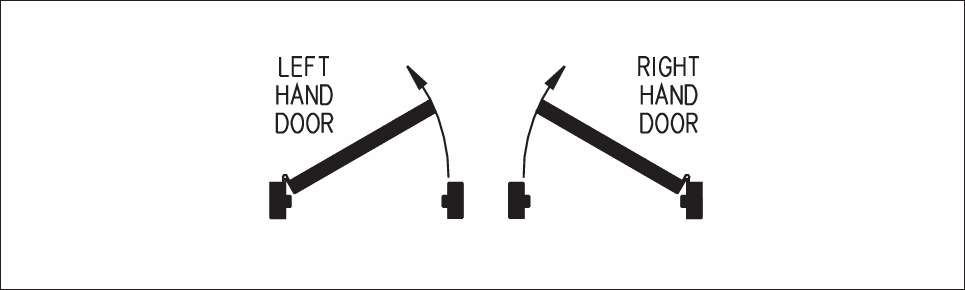

Handed Closers

Some door closers are handed. When approaching a door from the push side, if hinged on the left, it is a left-hand door; if hinged on the right, it is a right-hand door. For purposes of handing door closers, right-hand reverse bevel and left-hand are identical. Similarly, left-hand reverse bevel and right-hand are identical.

A Standard Closer and Template to Meet Your Needs

Occasionally, the physical limitations of the selected closer may not provide the desired functions or degree of opening. Standard templated locations may interfere with other applied hardware. In these situations, contact the LCN Applications Engineering Department for assistance. Customized installation templates or products may be available to solve a non-standard application.

Plates, Brackets, Adapters, and Other Special Pieces

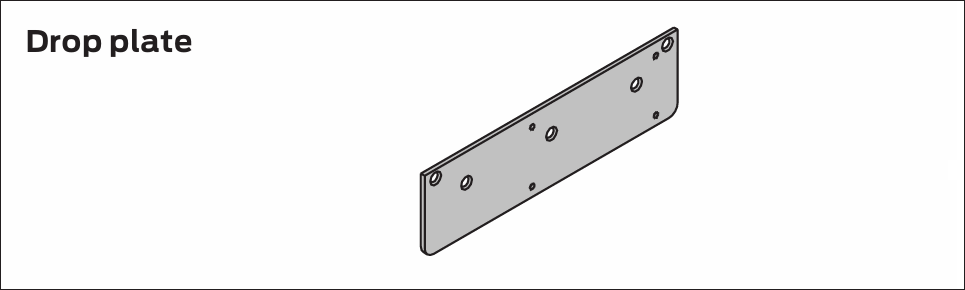

A drop plate is now commonly used to drop (lower) closers to meet special conditions or adapt a closer to door or frame surfaces that are not adequate for normal mounting patterns.

Specialized brackets, adapters, and parallel arm shoes are available to simplify the installation of closers with a variety of frame and door conditions. The most commonly used are listed with each closer. Consult LCN for assistance if you are unsure.

Fastener Options

LCN closers are shipped with Wood and Machine Screws (WMS) or Self Reaming and Tapping Screws (SRT) unless other fasteners are ordered. These screw packs are suitable for wood or properly reinforced hollow metal frames and metal or solid core wood doors. For wood door applications, LCN recommends the use of wood screws. For selected closers, metric machine screws are available in lieu of UNC/UNF machine screws.

When attaching closers to hollow core doors, optional Through Bolts (TB) are recommended to minimize crushing or squeezing the door. Through bolting can also provide a very strong mechanical connection for potentially abusive applications. Because the TB barrel extends completely through the door, the door thickness must be specified when ordering if it is other than 1 3⁄4" (44 mm). TBs are only available for 1⁄4 -20 machine screws.

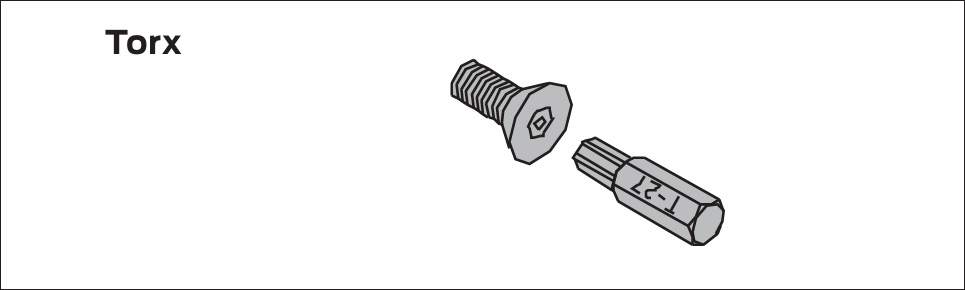

For high-security applications, Torx machine screws are available with most closers. These are standard for all exposed fasteners with high-security closers. Torx fasteners feature a hex lobular drive with a security pin in the center. They can only be installed or removed with a special set of bits available from LCN.

Desired Finishes

LCN powder coating provides superior protection against the effects of weather conditions and is an environmentally friendly process. The high quality, chip-resistant finish is far superior to any previously offered. Corrosion resistance surpasses 100 hours of salt spray testing (four times the industry standard). Non-metallic components also provide the same high resistance to the effects of the elements. All LCN products are shipped with a finish.

Custom Finishing Services

LCN offers custom finishing services to complement special installations. This provides a custom appearance and all the corrosion resistance inherent in the standard powder-coated finishes. It is recommended that the customer submit a physical sample of the desired custom finish with the closer order. Custom powder coat finishes are available at additional cost. A metal cover must be ordered when custom powder coat finishes are desired.

Plated Finishes

With some exceptions, visible components such as covers, arms, fasteners, and finish plates are available in plated finishes. Tracks are painted to complement the plated finish. Hidden assemblies such as cylinders and mounting plates are supplied with a powder-coated finish. Plated finishes are available at additional cost.

Special Rust Inhibitor (SRI) Process

For installations where a higher level of protection against weathering is required, LCN offers a Special Rust Inhibitor (SRI) process at an additional cost. Metal components receive an SRI pretreatment and a standard or custom powder coat finish. The SRI process with a powder coat finish exceeds the protection level available with powder-coated parts. SRI cannot be ordered with plated or anodized finishes. All closers must be shipped with a finish.

Installation Process

Before Installation of the Door Closer:

- Review the installation instructions provided with the door closer.

- Verify the desired installation and template with the hardware schedule. Review other applied door hardware for possible interference.

- Verify that the frame attachments and door hinges or pivots are securely installed.

- Verify that the door is hung properly and operates smoothly through its entire range of opening. Misalignment, sagging, or other conditions that prevent free movement of the door must be corrected prior to the installation of the door closer. LCN recommends < 1⁄4 lbf to open the door before installing closers for ADA applications.

- Check latching mechanisms for proper operation and release.

- Verify that the door and frame have specified reinforcements.

- Verify that all required tools are available.

To Complete the Installation:

- Follow the installation instructions and use fasteners provided with the closer.

- Use the template provided with the closer, layout, drill, and tap (for metal screws) the required mounting holes. Be sure to use the proper size drill bit and tap to ensure maximum holding power by the screws.

- For closers with adjustable spring power, adjust the cylinder spring power based on the width of the door as described in the installation instructions.

- The hydraulic backcheck main speed and latch speed regulation adjustments of the door closer have been adjusted at the factory to meet normal installation conditions. If further adjustments are required to the hydraulic regulation, follow the directions included with the installation instructions.

- Lightly wipe the cover and arm surfaces with a soft, clean, dry cloth to remove any dirt or smudges that occurred during the installation.