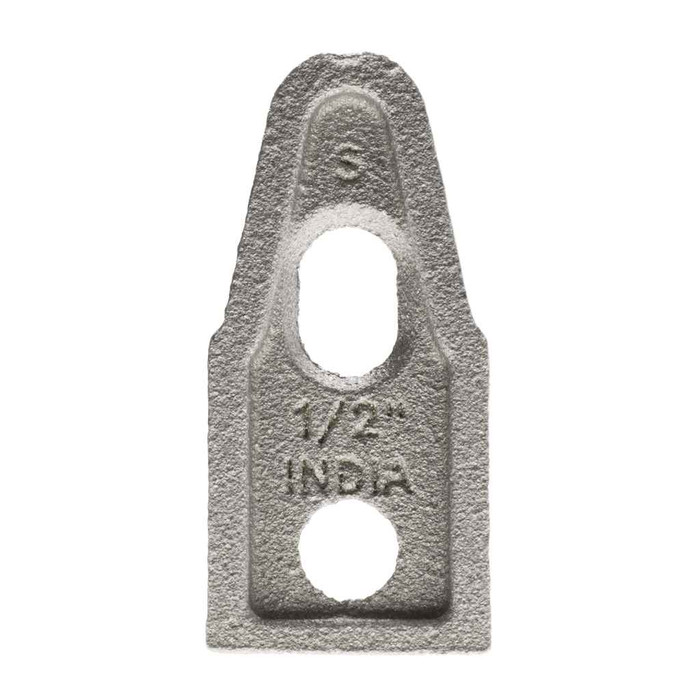

Bridgeport Fittings Aluminum Clamp Backs - 1.875" Height Conduit Spacing Solution

Cost-Effective Aluminum Construction for Professional Conduit Installation

Bridgeport Fittings Aluminum Clamp Backs deliver reliable conduit spacing performance with lightweight aluminum construction. These 1.875-inch height clamp backs provide essential space between conduit and mounting surfaces while offering a cost-effective alternative to steel or malleable iron solutions. Designed for use with aluminum straps, these clamp backs feature plain finish aluminum construction for dependable electrical installation support.

Professional Features & Benefits

- 1.875-inch Height: Provides optimal spacing between conduit and mounting surface for proper installation clearance and accessibility.

- Aluminum Construction: Delivers cost-effective performance while maintaining structural integrity for conduit support applications.

- Plain Finish: Offers clean, professional appearance suitable for visible installations and various mounting environments.

- RoHS, REACH & LEED Compliance: Meets environmental standards for responsible construction and green building requirements.

- Zinc Plating Corrosion Resistance: Provides enhanced protection against corrosion over time for long-term reliability.

- Aluminum Strap Compatibility: Specifically designed for use with aluminum straps for complete conduit mounting systems.

Technical Specifications

- Compliance Standards: Bridgeport straps are RoHS compliant, REACH compliant and LEED compliant

- Corrosion Resistance: Zinc plating offers higher corrosion resistance over time

- Cost Effective: Aluminum construction is a money-saving solution when more rugged steel or malleable iron are not n

- Country Of Origin: India

- Department: Electrical

- Division: Electrical H1

- Field Application: Provides space between conduit and mounting surface. For use with Aluminum straps.

- Product Finish: Plain finish

- Product Height: 1.875 in

- Product Material: Aluminum

- Sub Division: Electrical-E H2

Installation & Operation

- Mount the unit in a suitable location with appropriate clearance and access for connections and service.

- Connect utility and load conductors following applicable guidelines and the manufacturer's instructions.

- Wire generator or power input according to the provided voltage/phase specifications and compatible capacity.

- Configure any available load management or control features as supported by the provided specifications.

- Test automatic transfer or operational functionality and verify proper performance before placing into service.

- Complete final inspection and follow ongoing maintenance practices appropriate to the product category.

Professional Applications

- Commercial Electrical Installations

- Industrial Conduit Systems

- Residential Electrical Projects

- Retrofit and Upgrade Applications

- Multi-Unit Properties

- Professional Offices

- Retail Establishments

Why Choose Bridgeport Fittings Quality?

Bridgeport Fittings delivers proven reliability through aluminum construction that meets RoHS, REACH, and LEED compliance standards. The zinc plating provides enhanced corrosion resistance for long-term performance, while the cost-effective aluminum material offers professional-grade durability for demanding electrical installation applications.

Manufacturer Resources

Product Specs

- Compliance Standards:

- Bridgeport straps are RoHS compliant, REACH compliant and LEED compliant

- Corrosion Resistance:

- Zinc plating offers higher corrosion resistance over time

- Cost Effective:

- Aluminum construction is a money-saving solution when more rugged steel or malleable iron are not n

- Country Of Origin:

- India

- Department:

- Electrical

- Division:

- Electrical H1

- Field Application:

- Provides space between conduit and mounting surface. For use with Aluminum straps.

- Product Finish:

- Plain finish

- Product Height:

- 1.875 in

- Product Material:

- Aluminum

- Sub Division:

- Electrical-E H2